|

|

|

Outboard Design To check that were not overloading the hull it is necessary to take a stab at the drive system weight, after all were not building a submarine! To do this I use some stock components and masses working around some basic assumptions on power. The guesstimate uses a Lynch motor based drive package as its very simple, about as light as drives come and at this stage costs nothing!

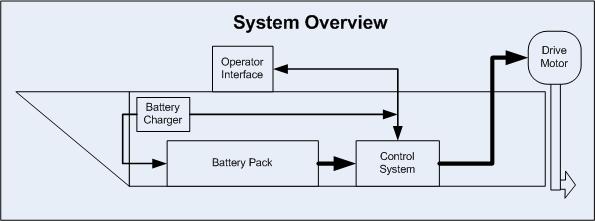

So the drive system estimate comes to around the same weight as 2 adult passengers, if there around my size anyway. The displacement hull will easily cope with this and more so we can open the design up to different drives and battery packages. As an engineer I now look to the architectural design and documentation, ADD, and the detailed design documentation, DDD, and this is where we start to drill down in to the project detail. This may seem like a lot of paperwork but this is the stage of the project that is only costing you time not your hard earned money. Its easy to rush out and buy lots of toys but what you really dont want is to be 1/2 way through the project and then ordering a widget because the one you have wont fit and worse still having a hand full of spare widgets come the end. ADD At the ADD stage the system overview is produced and it is posable to start detailing what components will be in the final system. This starts with a ‘what must be in it’ look to define our drive. |

|

|

We use our system requirements to check that we have all the components we will need and can then where required break the modules down further. As this is a simple drive system it could be argued that we are close enough for a architectural design and that were ready to move in to the detailed design document stage. Keen eyes may have noticed that in our basic system there’s no allowance of any ancillary equipment and we could go back and add this as a requirement if we felt it necessary but as this is intended to be a basic project we’ll not be adding this. What we will add however is a battery charge status monitor, or fuel gauge. So our requirements now read;

|

|

[Home] [Contact Us] [Gallery] [Tech Stuff] [Electric Outboard] [Sparrow #10] [Think!] [Links] [RDYC] [Wedding Private] |